How to Repair a Trident: A Practical DIY Guide

Learn how to repair a trident with a clear, safety-focused, step-by-step approach. This guide covers assessment, tools, materials, and finishing touches to restore balance and function.

In this guide you’ll learn how to repair a trident by assessing damage, selecting the right materials, and following a step-by-step process to restore balance and safety. You’ll find a full tools list, a step-by-step workflow, safety precautions, and maintenance tips to extend the life of the repaired piece.

Overview of repairing a trident

If you’re curious about how to repair a trident, this guide focuses on practical repairs for a wooden shaft with metal tines. While a trident can be a ceremonial or decorative piece, the same fundamentals apply to many shaft-and-torked-tine tools: assess damage, secure the components, and restore structural integrity. This article uses plain-language explanations, safety considerations, and actionable steps so homeowners and hobbyists can approach repairs with confidence. The goal isn’t just cosmetic renewal but restoring balance, rigidity, and safe handling. By following these techniques, you’ll understand the core concepts behind keeping a trident functional while avoiding common mistakes.

Throughout this guide, Home Repair Guide references and practical tips help you work with common materials like wood, steel, and epoxy. The aim is to provide a robust, repeatable method that you can apply to similar tools and ceremonial pieces while keeping safety at the forefront.

Assessing damage and planning

Before any repair, take a thorough inventory of damage. Inspect the shaft for cracks, warping, or rot; check the tines for bending, rust, or loosened rivets; and assess the joint areas where tines attach to the shaft. Photograph each issue角 and note areas that require disassembly or replacement. Plan your repair by prioritizing structural failures first, then addressing cosmetic defects. Decide whether you can restore the original hardware or if parts must be replaced with compatible rivets or dowels. A clear plan will prevent you from wasting time and will help you predict curing or drying times for any adhesives or finishes you use. When you’re dealing with especially long or heavy shafts, consider enlisting a second pair of hands to stabilize the piece while you inspect and measure.

If you’re going to replace any components, source compatible materials that match the original dimensions as closely as possible. This reduces imbalance and keeps the trident safe to handle. Home Repair Guide emphasizes measured planning, so you get a repair that lasts and remains visually cohesive with the rest of the piece.

Safety first: protective gear and workspace

Safety should be your top priority for any repair project. Wear safety glasses or goggles to protect your eyes from flying debris when grinding or drilling, and use sturdy gloves to shield your hands from sharp edges. A dust mask or respirator is advisable if you’ll be sanding or sanding epoxy or wood filler. Work in a well-ventilated area to avoid inhaling fumes from adhesives or finishes. Use a stable workbench or immobilize the trident in a vise to prevent slips. Clear the workspace of clutter and keep a water spray bottle handy to manage dust and sparks when necessary. Having a dedicated, well-lit space makes the task safer and more efficient, especially during precise steps like aligning tines or re riveting.

Disassembly and inspection

Disassembly should be deliberate and methodical to prevent further damage. Start by loosening any rivets or fasteners securing the tines, keeping small parts organized in labeled containers. If a tine is riveted, inspect the rivet hole for elongation or wear; if you see wobble once reassembled, you’ll need to replace rivets or reinforce with a dowel and epoxy. Inspect the shaft along its length for any hairline cracks or wood rot; small cracks can be stabilized with epoxy or wood filler, but larger cracks may require shaft replacement. When removing tines, avoid forcing components; gentle taps with a rubber mallet are often enough to free them without splitting the wood. After disassembly, clean any rust from the tine bases with a wire brush and wipe the parts dry before proceeding to repair or replacement.

Repair methods for shaft and tines

Repairing the shaft requires balancing strength with flexibility. For minor cracks, apply a two-part epoxy designed for wood, then clamp the section until fully cured. If there’s a deep crack or slight warping, sliding a wooden dowel into the shaft can provide internal reinforcement, then sealing with epoxy and sanding flush. For bent or rusted tines, straighten carefully with pliers or controlled heat if appropriate for the metal type, and remove heavy rust with a rust remover or wire brush. If a tine is severely bent or damaged beyond repair, replace it with a compatible replacement tine and secure with rivets or a small weld if you have the proper equipment and training. Precision alignment is critical to ensure even weight distribution and safe handling. After structural repairs, consider applying a penetrating sealant or varnish to protect exposed wood and metal surfaces from moisture.

Reassembly, finishing, and testing

Reassemble the trident with careful alignment to ensure all tines sit evenly around the shaft. If a new rivet is used, secure it firmly and verify there is no looseness by applying a small amount of lateral pressure. Sand the repaired areas smoothly so there are no sharp edges that could catch on clothing or skin. Apply a protective finish—such as a wood sealant on the shaft and a clear coat on metal parts—to resist moisture and corrosion. After finishing, test the trident’s balance by holding it horizontally at the grip and gently flexing the shaft to check for any give or unwanted movement. If there is any wobble, revisit the joints to tighten and reinforce.

Final inspection should look for consistent finish, tight joints, and balanced weight distribution. Home Repair Guide notes that a well-finished repair not only lasts longer but also looks more cohesive with the original piece. If the trident has ceremonial or decorative value, you may opt for color matching or traditional finishes that align with its historical or aesthetic purpose.

Maintenance to extend life

To prolong the life of your repaired trident, perform regular maintenance. Clean after use to remove moisture and residue, and re-apply protective finishes as needed, especially on the shaft where wood is exposed. Check rivets and joints every few months, tightening or reseating as necessary to prevent gradual loosening. Store the trident in a dry, cool place to minimize wood swelling and metal corrosion. If you notice new cracks or looseness, address them promptly to avoid larger structural failures. A simple maintenance routine saves time and preserves safety over years of occasional use.

Tools & Materials

- Safety gloves (nitrile or leather)(Protect hands from sharp edges and hot surfaces.)

- Safety glasses or goggles(Eye protection during grinding, drilling, or filing.)

- Dust mask or respirator(Prevents inhalation of dust and fumes.)

- Sturdy workbench or table(A stable surface for accuracy and safety.)

- Bench vise or clamp system(Keeps the trident steady during work.)

- Hammer and rubber mallet(For gentle adjustments and rivet setting.)

- Pliers (needle-nose and regular)(Grip, bend, and manipulate metal components.)

- Rivet set or rivet gun(If replacing tines with rivets; optional if welding not used.)

- Center punch and punch set(Marks for drilling holes for rivets or pins.)

- Metal file and/or rasp(Smooth rough edges and shape tines.)

- Sandpaper (grits 80-220)(Finish surfaces before coating.)

- Wire brush(Clean rust and prepare metal surfaces.)

- Epoxy adhesive (two-part)(Bond wood and reinforce joints.)

- Wood filler or epoxy putty(Fill cracks before finishing.)

- Wood dowel (matching thickness)(Internal reinforce for cracked shafts.)

- Protective sealant/varnish(Moisture resistance for wood surfaces.)

- Solvent and clean rags(Clean tools and surfaces after use.)

- Replacement tine segment or rivets(Use if original tines are damaged beyond repair.)

- Safety footwear optional(Extra protection in workshop environments.)

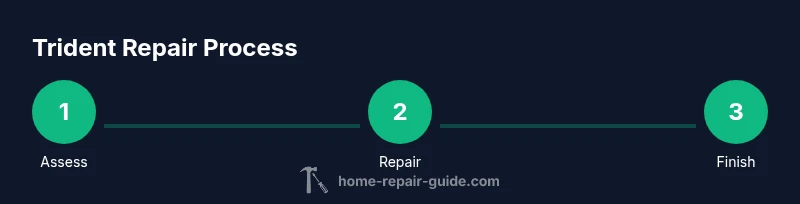

Steps

Estimated time: 2-4 hours

- 1

Assess damage and gather materials

Carefully inspect the shaft and tines for cracks, bends, rust, and loosened joints. Document each issue and set aside the required tools and replacement parts. Confirm you have a clean, dry workspace and enough lighting to work precisely.

Tip: Do a quick visual scan first, then measure critical dimensions to avoid surprises later. - 2

Secure the trident for disassembly

Place the trident in a bench vise or clamp system with protective pads to prevent surface damage. Ensure the head and tines are accessible without striking adjacent parts. Loosen any fasteners or rivets with appropriate tools, keeping small parts organized.

Tip: Use a wooden block between the vise jaws and the shaft to avoid dents or splits. - 3

Address minor shaft cracks with adhesive

If you find hairline cracks, mix a two-part epoxy and apply into the crack, then clamp until cured. Wipe away excess epoxy and let it cure following the manufacturer’s times. For deeper cracks, reinforce with a wooden dowel inserted into the shaft and sealed with epoxy.

Tip: Dry-fit before applying adhesive to ensure alignment remains true. - 4

Repair or replace tines as needed

Straighten bent tines carefully with pliers. Remove rust with a wire brush and treat the base where it attaches to the shaft. If a tine is damaged beyond repair, replace it with a matching segment and secure with rivets or welding (only if you have training and proper equipment).

Tip: Always verify even spacing and symmetry when adding a new tine. - 5

Reinforce joints and secure rivets

When rivets are reused or replaced, ensure holes are clean and aligned. Use a rivet gun or hammer and punch to seat rivets squarely. If using dowels, drill precise holes and apply epoxy to secure them firmly.

Tip: Test fit before final riveting to avoid misalignment. - 6

Seal, sand, and finish the surfaces

Sand all repaired areas to a smooth finish using ascending grit sandpaper. Apply a protective sealant or varnish to wood portions and a clear coating to metal parts. Allow adequate curing time between coats for best results.

Tip: Wipe surfaces clean between coats to prevent dust inclusions. - 7

Test balance and durability

After reassembly, perform a gentle balance test by lifting and rotating the trident. Check for wobble or looseness at every joint. If anything moves, revisit the joints and retighten.

Tip: Apply incremental pressure to confirm the repair holds under normal handling. - 8

Final inspection and safe storage

Do a final visual and tactile inspection for sharp edges or protrusions. Store the trident in a dry location away from direct heat or moisture. Create a simple maintenance schedule to perform periodic checks.

Tip: Document the repair steps performed for future reference.

FAQ

Is it safe to repair a trident at home?

Yes, with proper safety gear and basic tooling. Avoid high-risk repairs if you lack experience with sharpened edges or metalworking. Always work in a well-ventilated area and keep the workpiece secure to prevent accidents.

Yes, you can repair a trident at home if you follow safety practices and use the right tools.

What tools are essential for repairing a trident?

You’ll need a basic toolkit: clamps or a vise, screwdrivers or rivet tools, pliers, a hammer, a wire brush, a metal file, sandpaper, epoxy adhesive, and sealant. A drill and center punch are helpful for adding rivets or pins.

A basic toolkit with clamps, rivet tools, pliers, epoxy, and sandpaper is essential.

What should I do if the shaft is cracked near the head?

Do not rely on a single glue bond. Stabilize the crack with epoxy and a wooden dowel for internal reinforcement if needed. If the crack is severe, consider replacing the shaft to avoid failure during use.

Stabilize minor cracks with epoxy; replace the shaft if the crack is severe.

Can I reuse damaged tines?

Only if the tines are straightened, rust-free, and can be securely riveted or welded back in place. For bent or severely corroded tines, replacement is safer and more reliable.

Only reuse tines that are straight and securely attachable; otherwise replace.

How long does curing take for repairs?

Adhesives and finishes have varying cure times. Plan for several hours for handling and up to 24 hours for full cure before heavy use.

Expect several hours for handling and up to a full day for complete cure.

How should I maintain the repaired trident afterward?

Regularly inspect joints and rivets, reseal exposed wood, and store in a dry place. Reapply finish as needed to protect against moisture and corrosion.

Inspect regularly and reseal as part of routine maintenance.

Key Takeaways

- Assess damage thoroughly before starting.

- Use proper safety gear for all steps.

- Secure joints and align tines for balance.

- Adhere to adhesive cure times for lasting strength.

- Maintain the repaired trident with regular checks.