The Repair Act: A Practical Guide to Safe Home Repairs

Master the repair act with practical planning, essential tools, and step-by-step instructions. Home Repair Guide provides safety tips and techniques for reliable home repairs.

Learn to perform the repair act safely with practical planning, tool lists, and step-by-step instructions. This guide covers risk assessment, how to choose the right tools, and how to execute precise repairs. From drywall and plumbing to minor electrical fixes, you’ll gain durable results and confidence for future projects. According to Home Repair Guide, a careful approach reduces risk and improves outcomes.

What is the Repair Act and why it matters

The term repair act describes a deliberate, methodical approach to fixing issues in a home using proper planning, reliable materials, and safe techniques. It emphasizes preparedness, documentation, and durability, so fixes last longer and require fewer callbacks. For homeowners and renters, understanding this act helps you make wiser material choices, minimize disruption, and protect your living spaces. According to Home Repair Guide, adopting a standardized repair act mindset reduces mistakes and speeds up project completion. This mindset also feeds into broader maintenance practices, helping you build a long-term repair plan rather than tackling one-off fixes.

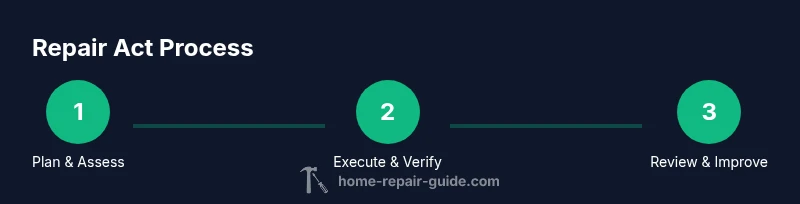

In practice, the repair act blends assessment, planning, execution, and verification. It’s not about rushing through a task; it’s about ensuring each step improves the system or surface being repaired. By framing repairs as acts of care—checking for hidden moisture, confirming fasteners are secure, applying sealant correctly—you create durable outcomes that stand up to daily use and seasonal changes.

Safety foundations for the Repair Act

Safety is the backbone of any repair act. Before touching tools, perform a quick hazards assessment: identify energized circuits, unstable surfaces, and the potential for falling debris. Put on appropriate PPE such as eye protection, gloves, and hearing protection when using power tools. Use a lockout/tagout procedure for electrical work where applicable, and never bypass safety features on equipment. If you’re unsure about a step, pause and seek guidance. The Home Repair Guide team emphasizes safety as a non-negotiable element of any repair act, because a single mistake can cause damage far beyond the initial problem.

Additionally, plan for ventilation when working with solvents, paint, or dust-producing tasks. Keep a clutter-free workspace and clearly mark exit routes. By prioritizing risk mitigation, you reduce the chance of injuries and accidental damage during the repair act.

Planning your Repair Act: scope, materials, and timing

Effective planning starts with a well-defined scope. Break the project into concrete tasks, estimate materials, and set a realistic timeline. Create a simple checklist that includes measurements, material compatibility, and safety steps. If you’re replacing components, verify compatibility with existing structures and ensure you have spare parts on-hand. A clear plan helps you avoid mid-project trips to the hardware store and reduces downtime in your home.

Consider potential downtime for occupants, especially in kitchens, bathrooms, or shared living areas. Schedule the repair act during off-peak hours if possible and communicate expectations to household members. Home Repair Guide’s guidance stresses documenting baseline measurements and any observed conditions (water intrusion, wobble, or misalignment) so you can track improvements after completion.

Environmental checks and permitting considerations

Some repairs require more than just a toolbox and sealant. Electrical, plumbing, or structural changes may fall under local codes or require permits. Always check with your local building department or a licensed professional if you’re unsure. For minor tasks, simple safety checks and proper disconnects usually suffice. If permits are needed, plan ahead to avoid delays and penalties. This step is essential for long-term reliability and compliance with code requirements, which is why the Home Repair Guide team advises including permit considerations in your early planning stage.

As you prepare, test for moisture, insulation integrity, and air leaks around the work area. These checks influence material selection and sealing methods, ensuring the repair act improves energy efficiency and comfort in your home.

Tools and materials: essential and optional

Selecting the right tools and materials is critical for a successful repair act. Essential items should include a measuring tape, screwdrivers, a level, a drill/driver, safety gear, caulk, sealants, and appropriate fasteners. Optional but helpful items include a stud finder, a non-contact voltage tester, a moisture meter, and specialty adhesives for high-stress joints. Always choose quality components suited to the task, such as corrosion-resistant screws for outdoor repairs or silicone sealants for plumbing connections. A well-chosen kit reduces frustration and improves durability over time.

Keep a written materials list with part numbers or descriptions and cross-check it against your plan before buying. If you’re unsure about a material choice, ask for guidance from a hardware associate or consult manufacturer recommendations. The Repair Act is about doing it right the first time, not rushing and redoing the work later.

Step-by-step execution overview for a typical repair act

A repair act often follows a logical sequence: assess, isolate hazards, gather materials, prepare the area, execute repairs with proper technique, and verify results. This overview helps you stay organized and reduces last-minute surprises. Expect to encounter small surprises—like mislabeled wires or hidden damage—so build a modest contingency into your plan. The key is to maintain control of the workspace and to verify each step’s outcome before moving on. This mindset aligns with the goal of achieving durable improvements rather than quick, temporary fixes.

Troubleshooting during a repair act

When things don’t go as planned, pause, reassess, and don’t force solutions. Common issues include misaligned panels, shifting loads, or seepage around joints. Recheck measurements, reseat components, and ensure all safety devices remain engaged. If a fix isn’t holding, step back and confirm compatibility of materials, or consult product manuals for recommended installation techniques. Keeping a calm, methodical approach minimizes mistakes and preserves the integrity of the repair act.

Post-repair review and clean-up

After completing the repair act, perform a thorough review. Re-test all functions, inspect for gaps or misalignments, and verify the area is clean and safe. Proper clean-up includes safely disposing of waste, labeling any remaining components, and restoring the space to its regular use. Document what was done and any materials used for future reference. A clean, well-documented project reduces confusion if you revisit the area later and supports better maintenance planning.

Building a repair act checklist for future projects

Create a reusable checklist that captures your planning steps, safety requirements, tool readiness, and verification tasks. A good checklist reduces cognitive load during a new project and helps you stay consistent. Include sections for scope, risk assessment, permit status, material quantities, and a post-work verification. Over time, this becomes an invaluable resource for reliable, repeatable home repairs.

Tools & Materials

- Safety goggles or face shield(ANSI-rated; protect eyes from debris and splashes)

- Work gloves(Durable, cut-resistant gloves for grip and protection)

- Dust mask or respirator(Use for dust, adhesives, or solvents; select according to task)

- Ear protection(Earplugs or muffs when using loud tools)

- Measuring tape(Minimum 16 ft/5 m; ensure accuracy for fit)

- Screwdrivers (Phillips and flat-head)(Professional-grade, magnetic tips preferred)

- Drill/driver with bits(Drill bits suitable for material; include a countersink bit)

- Level and square(Helps ensure true alignment and plumb/flat surfaces)

- Caulking gun and sealant(Choose silicone or acrylic based on application)

- Caulk remover or utility knife(For surface prep and clean joints)

- Non-contact voltage tester(Optional for electrical checks in non-live environments)

- Moisture meter (optional)(Useful for detecting hidden dampness behind walls)

Steps

Estimated time: 2-6 hours

- 1

Assess the problem

Identify root cause and define success criteria. Document measurements and visible conditions, such as gaps, leaks, or movement. This helps prevent scope creep and guides material selection.

Tip: Take photos and notes before disassembly to track changes. - 2

Isolate hazards and power down

If electrical or plumbing is involved, turn off the relevant power or water supply. Use testers to verify de-energized states before touching components.

Tip: Lockout/tagout when working with circuits that could be accidentally powered. - 3

Gather materials and prepare workspace

Collect all tools and replacement parts. Lay down a drop cloth, protect nearby surfaces, and ensure adequate lighting. This prevents interruptions and keeps the area organized.

Tip: Label containers for fasteners and small parts. - 4

Execute the repair with proper technique

Follow manufacturer guidelines or established best practices. Use correct fasteners, apply sealants evenly, and maintain clean joints. Verify that components are seated and aligned before testing.

Tip: Avoid over-tightening; it can strip threads or crack materials. - 5

Test and verify results

Check function, leaks, and alignment. Re-test after any adjustments. Look for movement, looseness, or unexpected noises that indicate ongoing issues.

Tip: Run a small-load test where applicable to confirm stability. - 6

Cleanup and restore area

Remove waste, reinstall covers, and return the space to normal use. Document the work and store tools properly for next time.

Tip: Dispose of hazardous materials according to local regulations.

FAQ

What is the repair act and why should I follow it?

The repair act is a structured approach to home repairs that emphasizes planning, safety, proper materials, and verification to achieve durable results. Following it reduces mistakes and increases reliability.

The repair act is a careful, structured approach to home repairs that emphasizes planning and safety to get durable results. It makes future projects easier and more reliable.

Do I need permits for home repair tasks?

Permit requirements vary by task and locality. Check with your local building department before starting projects that involve electrical, plumbing, or structural work. When in doubt, consult a licensed professional.

Permits depend on the task and where you live. For safety-critical work, verify if a permit is required and consult a professional if unsure.

What PPE is essential for most repairs?

At minimum, wear safety goggles, gloves, and hearing protection when using loud or dusty tools. A respirator or mask may be needed for adhesives, paints, or solvents.

Wear eye protection, gloves, and hearing protection. A mask or respirator may be necessary for fumes or dust.

Can I perform most repairs myself?

Many small repairs are doable for homeowners with basic skills and the right tools. Complex structural or electrical work may require a licensed pro to meet safety and code requirements.

Most small repairs can be DIY with the right tools, but big or safety-critical tasks should be handled by a professional.

How long does a typical repair act take?

Duration depends on scope, materials, and any unexpected issues. Plan for several hours to a full day for substantial tasks, with breaks as needed for safety.

It varies, but expect several hours to a day for larger repairs.

What should I do if a repair act goes wrong?

Pause immediately to assess the cause, re-check safety, and revisit the plan. If necessary, consult manuals or a professional to avoid further damage.

If something goes wrong, stop and reassess. Check safety, inspect the plan, and seek help if needed.

How can I ensure future repairs are easier?

Document decisions, store spare parts, and build a personal repair act checklist. Regular maintenance reduces large fixes and keeps systems reliable.

Keep notes, stock commonly used parts, and use a checklist. It makes future repairs quicker and more reliable.

Watch Video

Key Takeaways

- Plan the repair act before touching tools.

- Prioritize safety with PPE and proper isolation.

- Use the right tools and materials for durable results.

- Verify results and document outcomes for future projects.